|

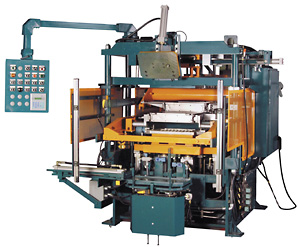

With the state-of-the-art Harrison flaskless matchplate mold machine, Buffalo Metal Casting has taken a major step forward in automated mold-making technology designed to boost productivity on behalf of its customers. System features and capabilities include:

Productivity Gains for our Customers

-

One operator can produce a mold every 40 seconds

-

Plate changes can be made in 60 seconds

-

Cores can be set while the cope is being made

-

Mold push-off can be done manually or automatically while the drag is being made

-

Adapted to our existing sand system and pour line

-

Existing patterns can be used 100 pattern programs stored in memory for quick call-up

-

Risers and chills can be set quickly and easily

-

More consistent mold quality provides predictable results

-

Consistent production improves delivery and increases capacity

System Capability and Flexibility for Customer Molds

-

Run jobs requiring anywhere from one mold up to dedicated continuous production

-

Special molding capability including contour molding, special peening, open risers, chills, and multiple sprue locations

-

Flask capacity to 14" x 22" - up to 6" over 8" with single closing pin system

-

Variable mold height - any combination up to the maximum flask capacity

-

Custom flask sizes can be used to suit existing patterns

-

Pattern height capacity to 4-1/2" from parting line

-

Recommended pattern plate thickness of 1" (without thin-pattern option)

-

Allen-Bradley PLC for reliability and flexible machine functions

-

Table impact vibrator for packing sand during the fill; pattern vibrator for mold stripping - manual or automatic

|

716-874-6211

716-874-6211 716-874-6211

716-874-6211![]() Metals Cast and Capacities

Metals Cast and Capacities![]() Casting Methods

Casting Methods